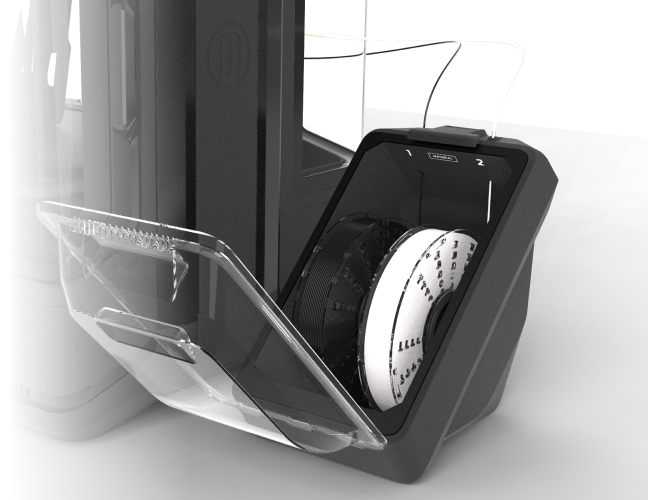

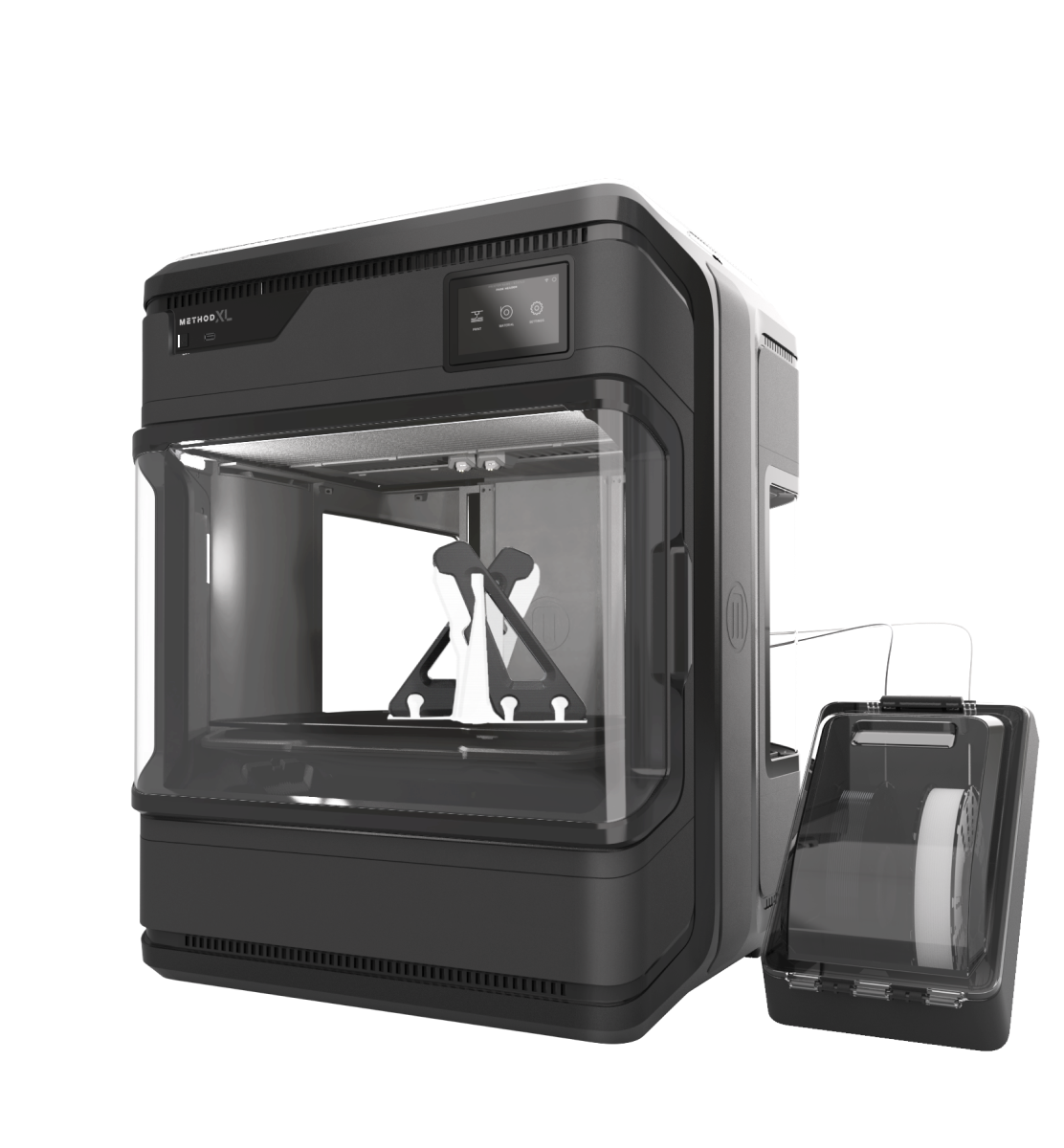

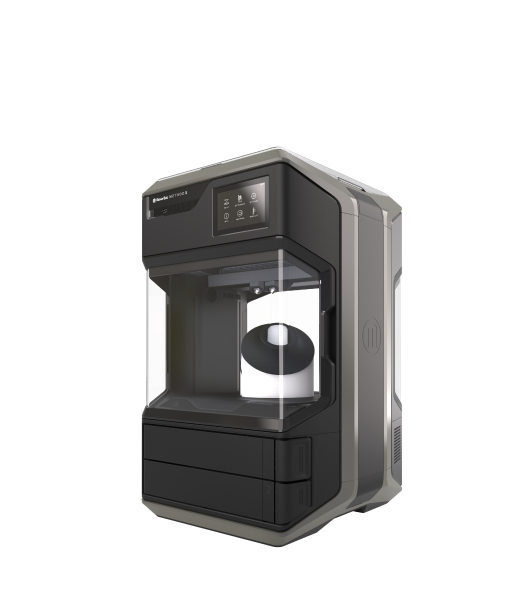

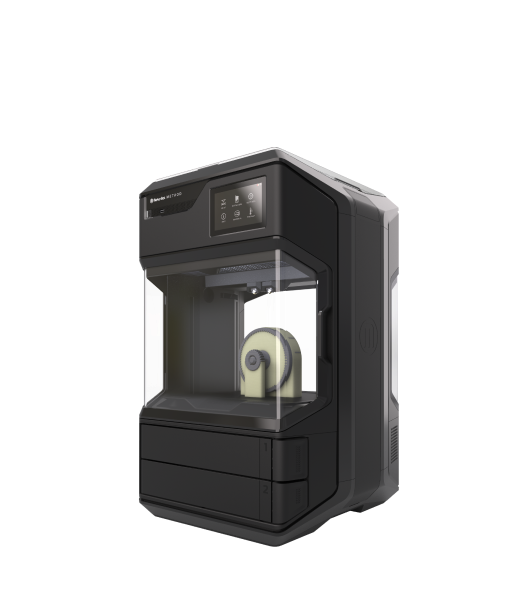

No compromise.

Extra large build volume

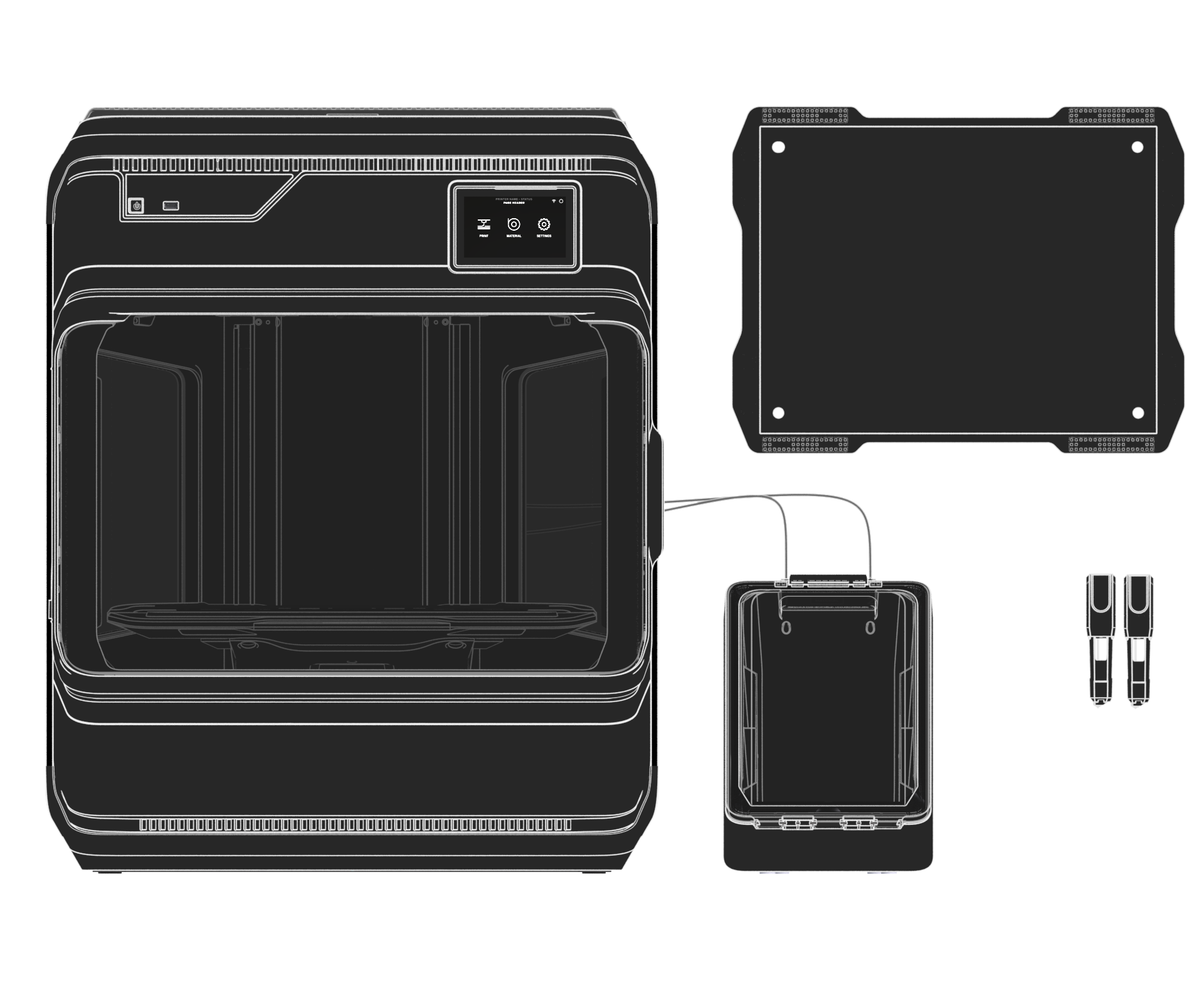

With the largest build volume of any UltiMaker 3D printer, the Method XL is the ultimate 3D printing solution for large-scale projects. Print with industrial-grade materials and exceptional dimensional accuracy without the need to compromise on the size of your parts.

Dual extrusion build volume (XYZ)

x = 305 mm

12 inches

y = 305 mm

12 inches

z = 320 mm

12.6 inches