-

3D printers

Back

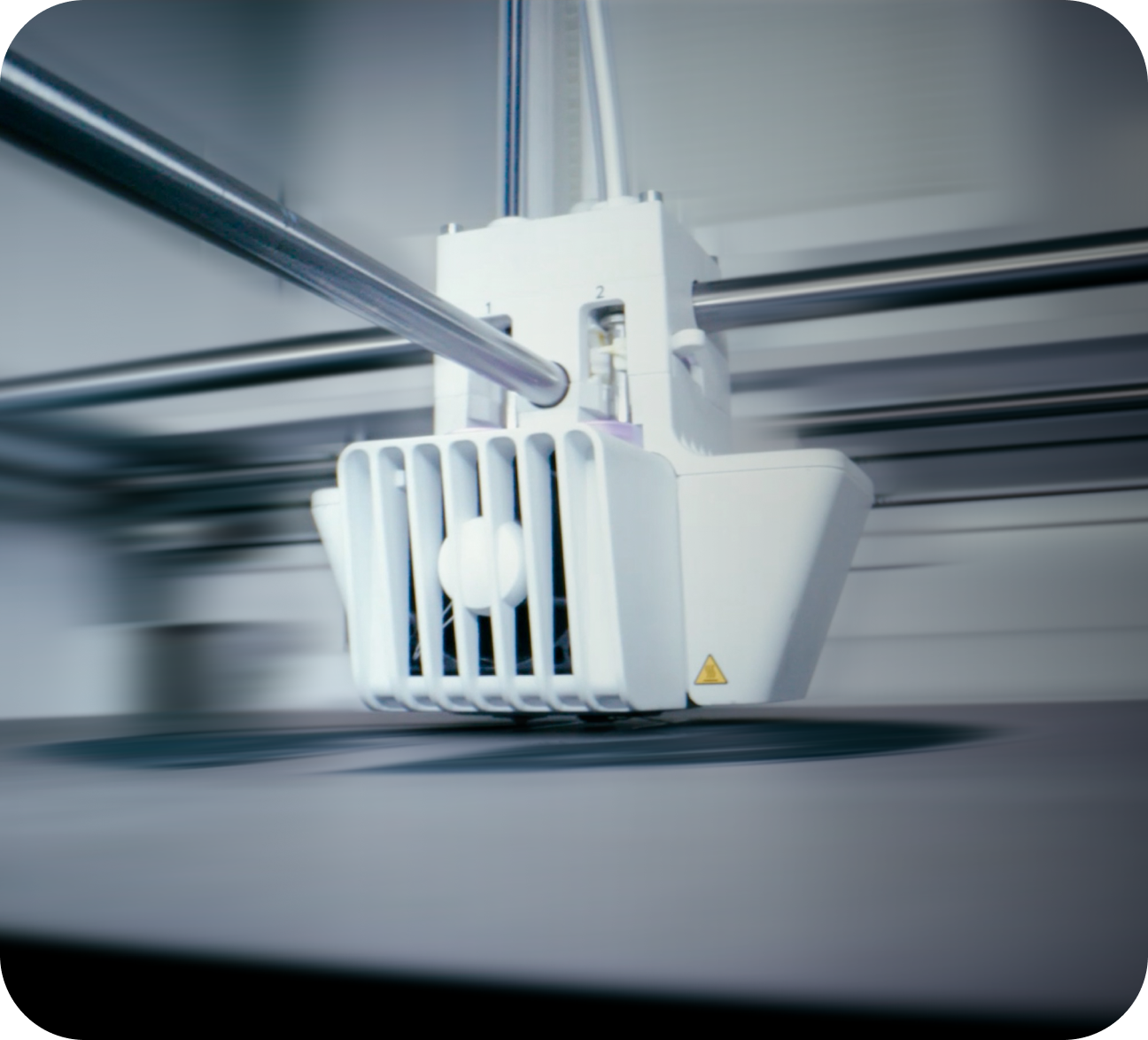

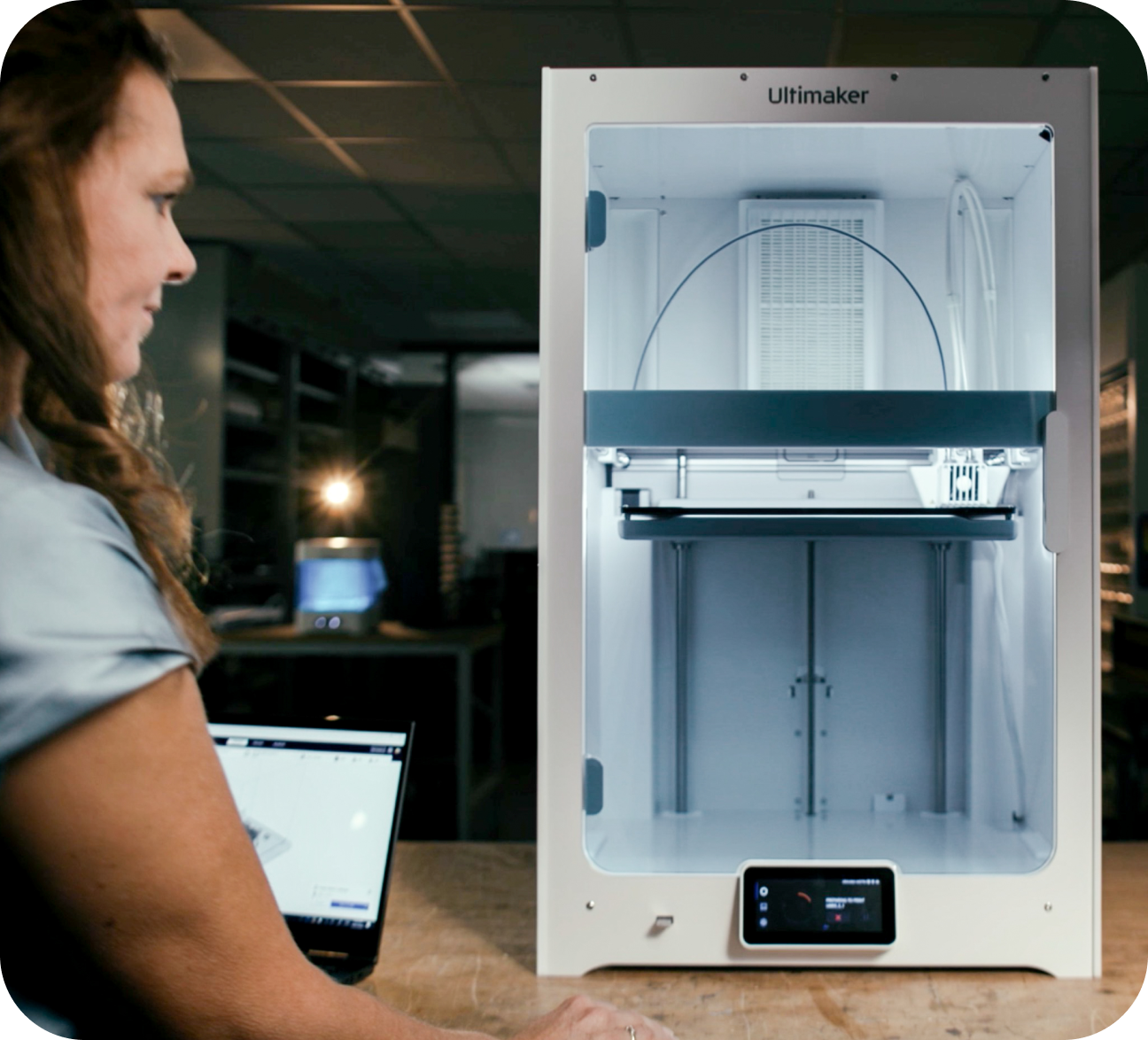

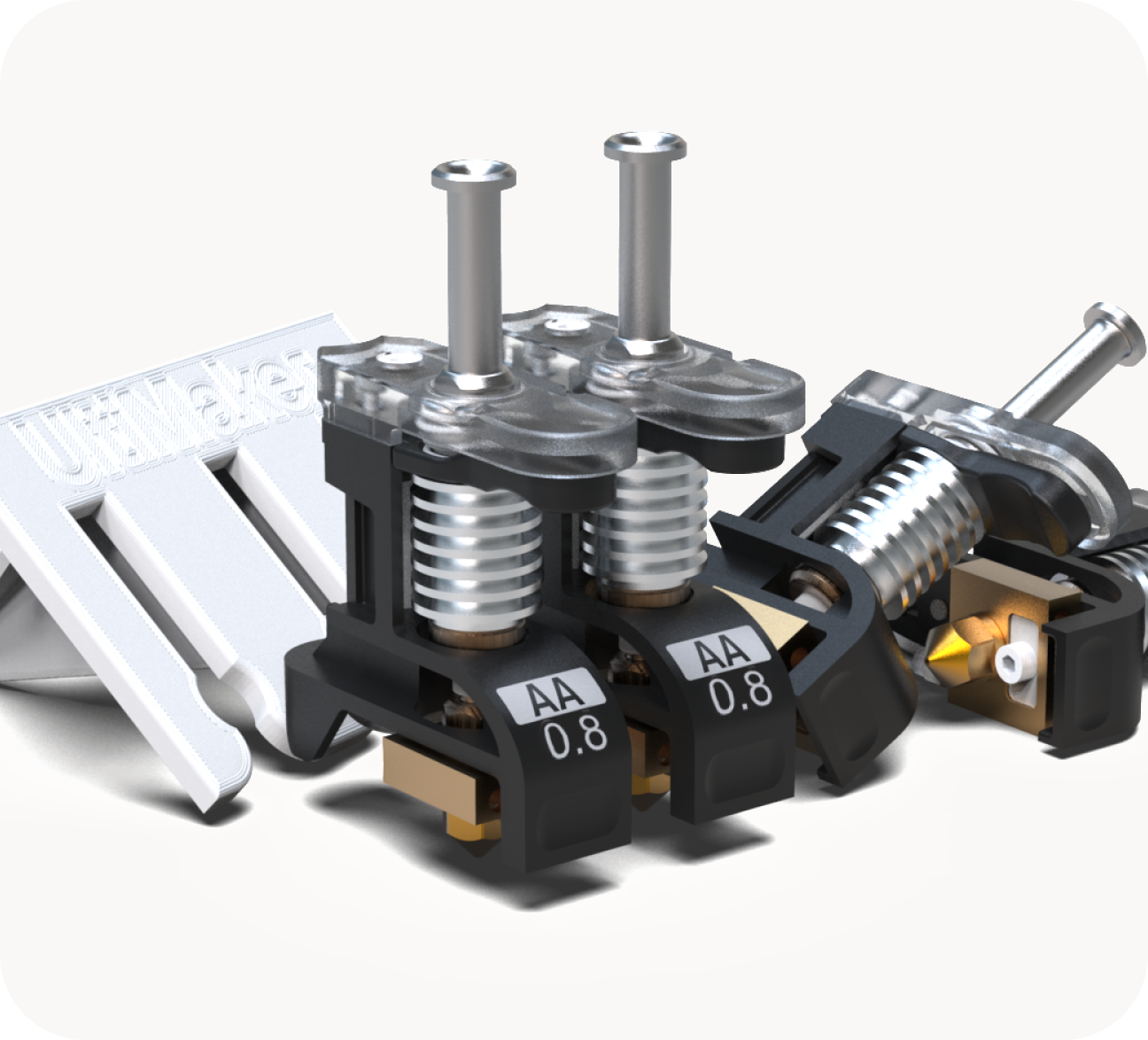

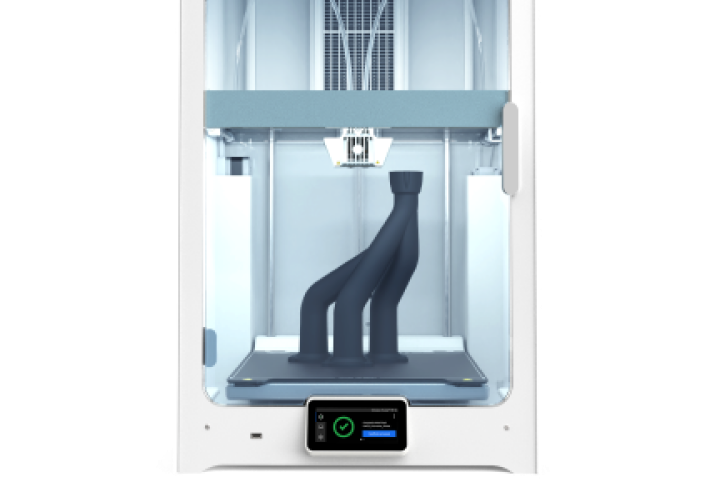

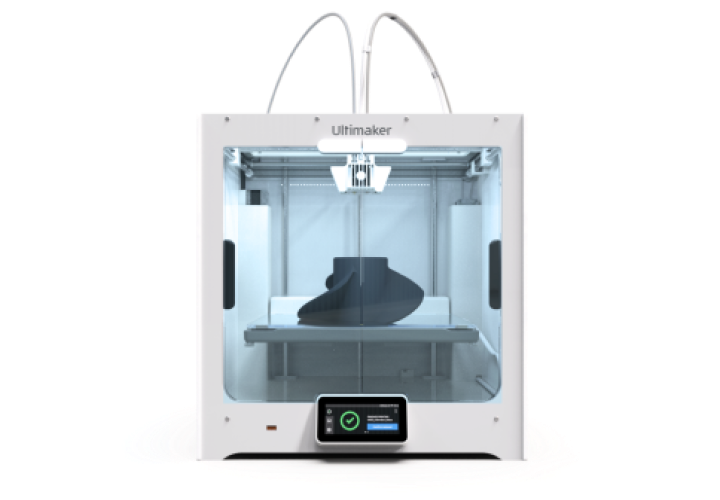

S series 3D printers

Unlimited application potential.

Method series 3D printers

Specialized for engineering applications.

-

Materials

Back

S series materials

Over 280 materials to choose from.

Method series materials

From polymers to composites to metals.

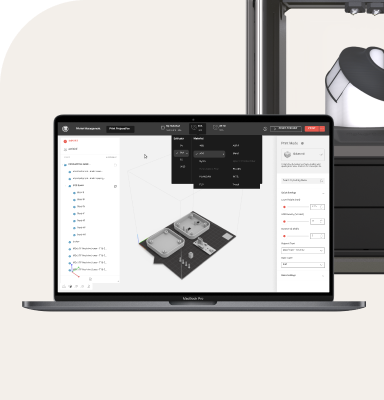

- Software

-

Applications

Back

Automotive

Optimize production processes

Defense

Keeping defense assets operational

Manufacturing

3D print custom parts and tools

Product development

Take your designs to the next level

- Learn

- Support